THE 3D PRINTING PROCESS

The new insole blanks are manufactured from thermoplastic polyurethane by means of a selective laser sintering (SLS) printing process. The fine powder particles are fused (sintered) by a laser and then bound together layer by layer. Through this process, the stability and elasticity of every single zone within the structure can be adapted. All the while using just one material.

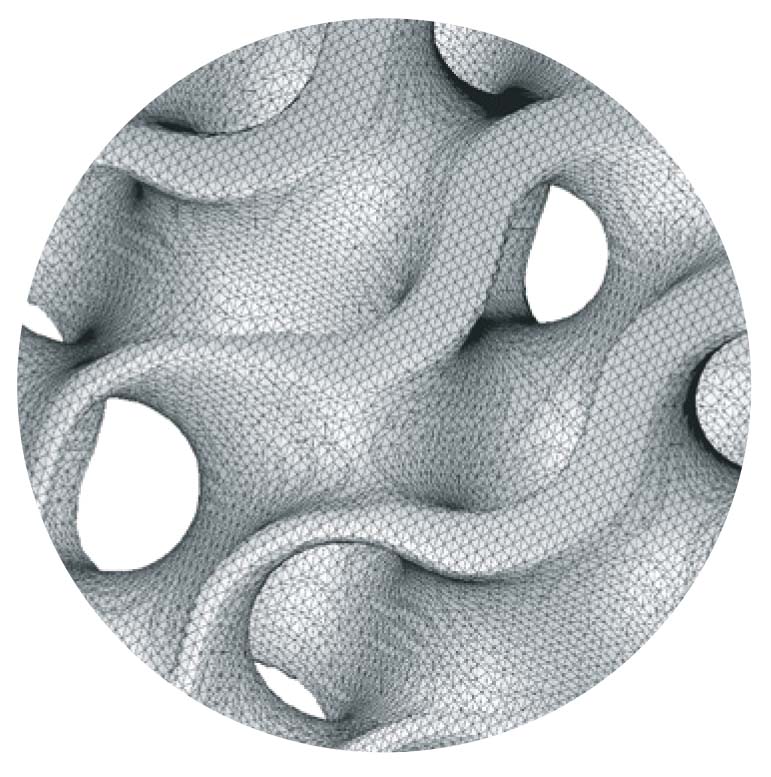

THE STRUCTURE

The extraordinary thing about the Novaped 4D is its mesh-like printed structure, with its 3D surface characterised by 12 million triangles. The gyroid structure is derived from the natural world. It can be seen in butterfly wings, for example – evidence of how high stability and lightness can be optimally combined. The isotropic structure is equally stable/elastic in all spatial directions, meaning that when weight is put on the structure, the pressure distribution on the foot is completely homogeneous. By varying the structure thickness, the gyroid allows for the production of an insole blank that is individual to every foot.The base

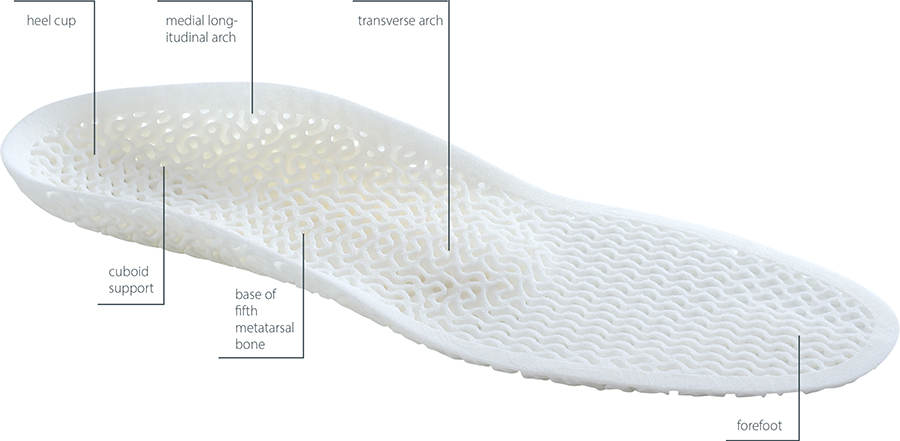

Anatomy of the insole blank:

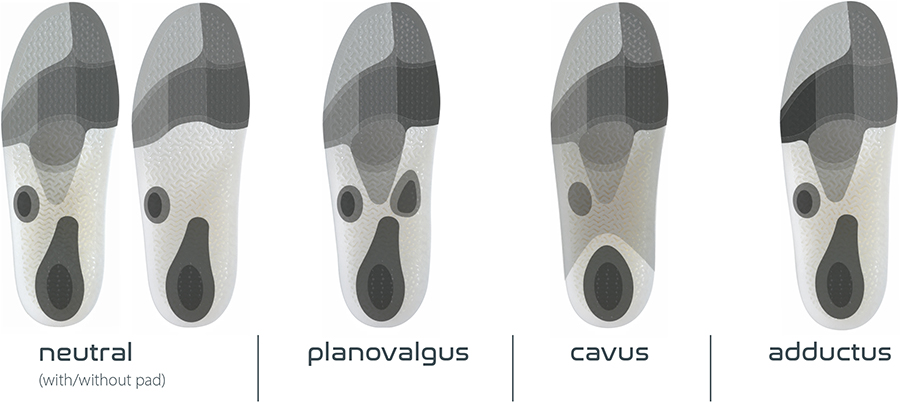

This process offers infinite possibilities for designing the insole. To reduce the complexity of such a huge range of options, we have created a selection of blanks that optimally suit different types of feet.You can choose between these types:

- neutral with pad

- neutral without pad

- adductus

- cavus

- planovalgus

Each of the five variants has its own topologies that match the respective foot types. Every single insole blank is the result of a wealth of experience and expertise – but that alone is not enough to create a perfect, precise and individual foot care product: now you have to define the DNA of the insole using the fourth dimension, the pressure map.

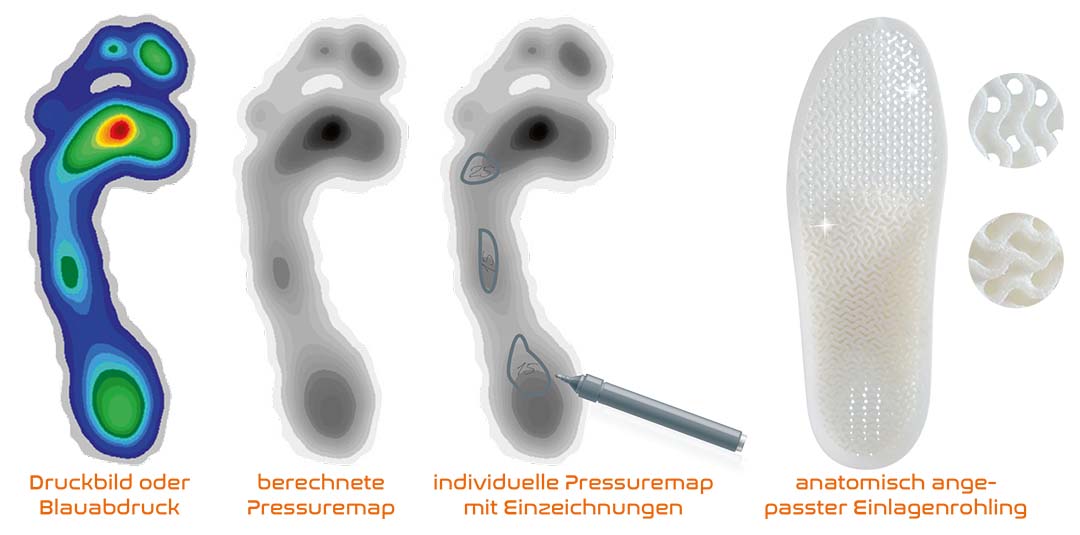

PressuremapTradition meets perfection

Our software lets you upload your patient data – whether in the form of foam foot impressions, blueprints, foot scans or printed images. You then get an individual pressure map and unique 3D printed insole for each of your patients. The structure thickness are automatically calculated through the placement of different shades of grey, which allows for the desired degrees of hardness to be selectively defined.

You customise the blank by either drawing in your own zones on the image or in our digital painting tool. A pressure map is automatically generated from this.

4D pressure mapNow you define the DNA!

- Mission Alpha: select and order one of the five insole blanks

- Mission Beta: select one of the five insole blanks, customise the hardness zones and order